Holesaws & Accessories ▼

Bandsaw Blades ▼

Power Tool Accessories ▼

Food Industry ▼

Precision Hand Tools ▼

Construction Hand Tools ▼

View All Holesaws & Accessories

- Bi-metal

- FCH - Fast Cut

- DCH - Deep Cut

- CSC - Cordless

- Carbide

- SM - TCT

- CTD - TCT Deep Cut

- MPH - TCT Multi-Purpose

- CT - Carbide Tipped

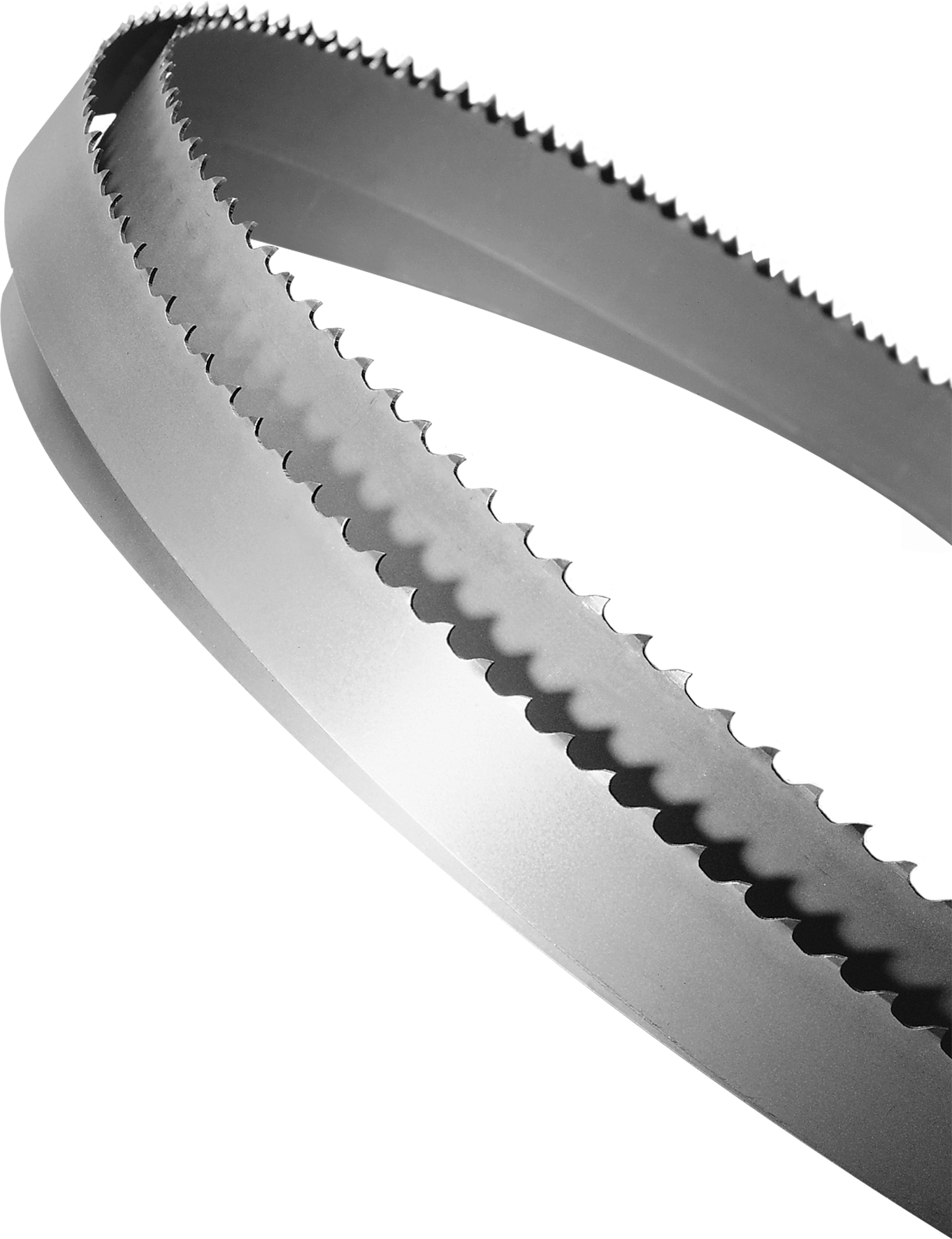

View All Bandsaw Blades

- Bi-metal

- TENNAX-PRO

- Primalloy™

- Intenss™ PRO-VTH

- Intenss™ PRO

- Intenss™

- Intenss™ PRO-DIE

- Univerz™

- Band Knives

- High Carbon Steel

View All Power Tool Accessories

- Jigsaw Blades

- Wood Cutting Bi-Metal Unique™

- Metal Cutting Bi-Metal Unique™

- Multi Purpose Bi-Metal Unique™

- Dual Cut™

- Jigsaw Blade Kits

View All Precision Hand Tools

- CALIPERS & DIVIDERS

- Spring-type Calipers

- Carpenters’ Dividers

- Firm and Lock-Joint Calipers

- Vernier Calipers

- Dial Calipers

- Electronic Calipers

- DIAL INDICATORS & GAUGES

- Dial Test Indicators

- Dial Indicators

- Thickness Gauges / Feeler Stock

- Telescoping Gauges

- Centre Finders

- Small Hole Gauges

- Strain Gauge

- RULES, SQUARES & PARALLELS

- Combination Squares

- Squares

- Precision Straight Edges

- Precision Steel Rules

- Bevels and Steel Protractors

- Adjustable Parallels